Although the United States military remains the principal operator of Power Armor, select private corporations have access to technology. Salvaging Power Armor is also difficult, as the amount of firepower necessary to accomplish this feat renders armor useless. Power necessary for a unit to operate autonomously comes from the Fusion Power plant integrated into the chassis suit, typically loaded on factory floor with fuel to last hundred years of moderate use. Beyond general revisions, large number of upgrades and custom internals have been developed for various Power Armor units, to increase their flexibility and performance on the battlefield. Each represents an incremental upgrade over the preceding model. The basic version of each Power Armor is designated model-letter is usually omitted in this case-with subsequent revisions and upgrades distinguished using sequential letters: B, C, D, E, and F. Naturally, enhanced strength also allows use of hard armored plating that would otherwise be impossible for soldier to carry with ease.

Safety of airborne deployments depends primarily on the model of armor, with survivable height for early T-60 models being about one hundred feet, increasing to more than three times height in later iterations. Of note is the integrated hydraulic shock absorbtion system, which allows operators to jump from major heights without damage. Operator Control Armor indirectly, using manipulators that steer hands and feet, while being safely isolated from the environment.

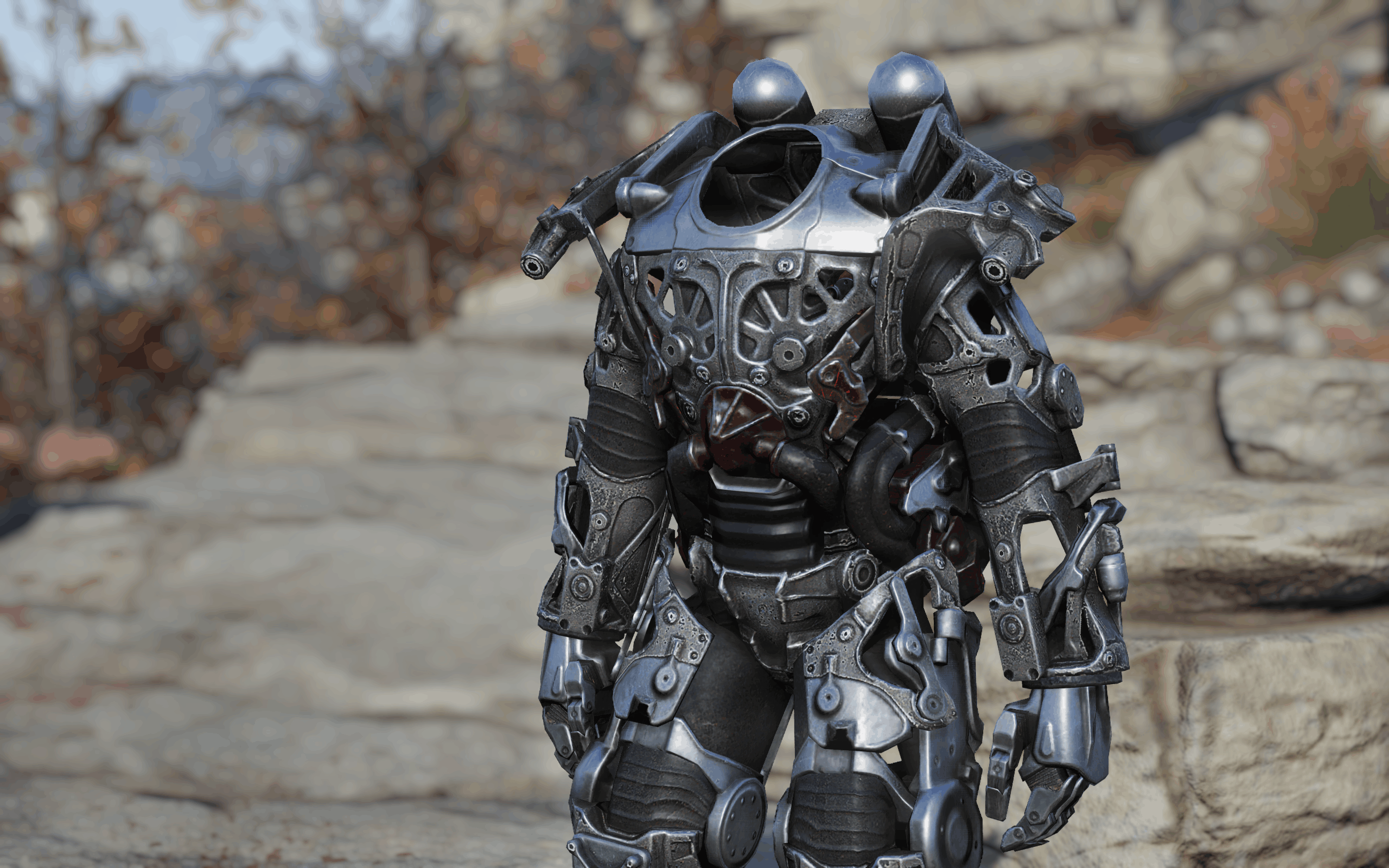

Each Power Armor is built around West Tek Power Armor frame with an internalized servomotor system, providing increased strength, resistance to trauma, and radiation protection. All Power Armor models in the United States share a common heritage and basic design.

0 kommentar(er)

0 kommentar(er)